National recognition for CISDigital®, now a multi-sector industrial internet platform

Date:2023/10/20 Source: CISDI

China’s Ministry of Industry and Information Technology has awarded CISDigital® cross-sector industrial internet platform status.

The world’s first applied metallurgical full-process industrial internet platform, CISDigital has helped industrial enterprises to collect and deposit their data, knowledge, model and application, and supported their multi-dimensional innovations in production processes, tech systems and organisational management.

The platform features a core infrastructure for digital, intelligent production control and operations, utilising CISDI’s industrial engineering and digital construction experience.

It applies ‘domain knowledge plus digital tech’ to enable massive data governance, with borderless connection capability and cloud-edge coordination. Data is utilised as a standardised, asset-oriented factor, unleashing full productivity potential.

Continued innovations in the platform’s mechanism model, smart sensing, analysis and knowledge retention are increasing China’s industrial digitalisation and high-quality developments.

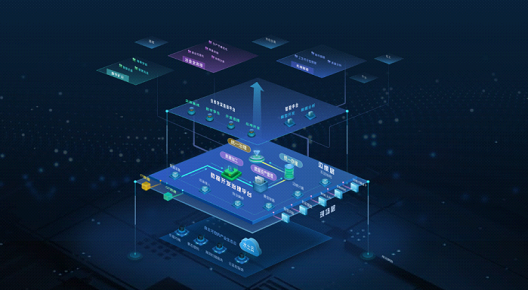

A screenshot of the CISDigital® industrial internet platform

An application setting of the CISDigital® industrial internet platform

✧ Tapping the full potential of data values by renovating the conventional ISA95 multi-layer structure

The conventional multi-layer structure for industrial information tech has caused severe data isolations, which made it difficult for managers to holistically control a production process, and failed to achieve comprehensive management via plant-wide data.

The CISDigital, a renovated industrial internet platform, removes data isolations by connecting all data from the production process and manages the data as an asset.

Platform-users can quickly compose their personalised smart applications, thus enabling companies to continuously innovate their intelligent manufacturing capabilities. Their decision-making becomes more scientific and accurate.

✧ Forming 2,000 industrial APPs in nine areas based on ‘domain knowledge plus digital tech’

The CISDigital platform has made continued advancements in unified data governance, agile development and domain knowledge integration, with data at its core. Its application scenarios are focussed on responding to data, business and smart categories.

Based on ‘domain knowledge + digital tech’, the platform has incorporated the following emerging technologies: industrial mechanism, process model, industrial operations tech and internet of things, big data, cloud computing and artificial intelligence.

It holds over 2,000 applications spanning nine areas - safe production, energy conservation and emission reduction, quality control, supply chain management, research design, manufacturing, business management, warehouse and logistics and ops management.

The platform’s hardware and software tech and products - which include CISDigtial-TimeS, CISDigital AI and edge computing gateway T800 and I800 - have been awarded 89 patents.

✧ Innovative intelligent manufacturing solutions to full metallurgical processes is creating an annual benefit of US$ 688 million

Since 2018, the platform has been operating at over 100 benchmark enterprises in 18 industries, from mining to ferrous and non-ferrous metallurgy, the chemical industry and the construction sector.

Platform-based products and solutions have been implemented globally creating US$ 688 million in annual benefits for our customers.

The CISDigital platform has enabled CISDI Information Tech Co to build more than 30 standout intelligent manufacturing projects - from production lines to smart factories. The CISDI-built Digital Plant is the first in the world to be based on a unified platform.

Baowu Shaogang

Baowu Shaogang’s integrated, intelligent control platform in Guangdong, China, is a world first for ferrous metallurgy.

It was the first time the centralised, massive applications of internet of things, mobile internet, big data and cloud computing in the conventional process industry had ever been achieved within the sector.

Shaogang’s smart manufacturing has enabled the removal of 436 workers from dangerous working zones, has integrated 32 work zones and made analysis and diagnosis on over 100,000 data of equipment and production.

Yongfeng Steel

Yongfeng Steel’s Lingang digital plant in Shandong, China, is based on the unified platform, featuring innovative system architecture which transforms regional intelligent manufacturing across the entire plant.

Lingang’s production cost per tonne of slab has been reduced by at least US$ 22.02 compared with costs at Yongfeng’s HQ.

Hongsheng Copper Corporation

The CISDigital industrial internet platform was integral to the development of China’s first digital copper smelting plant at Hongsheng Copper Corporation, for China Nonferrous Metal Mining Group (Daye).

It was critical to the development of digitalised production and operation.

The platform’s smart applications are creating a high standard of coordination, lean production management and optimal decision-making. This enables smart operation, smart control and decision-making throughout the copper smelting process.

Hongsheng Copper’s cost of copper smelting has been reduced.